By using wireless switching devices for two-component injection moulding, steute is able to close the gap between the need for technical flexibility and the solutions currently available in the marketplace.

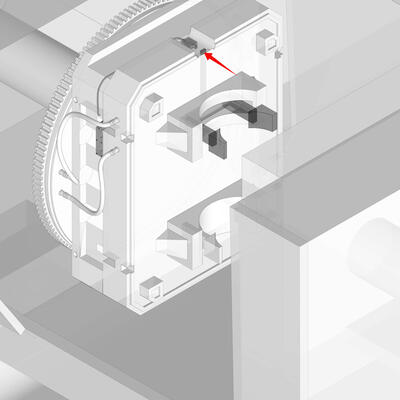

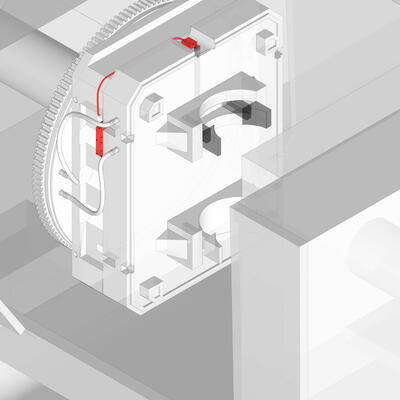

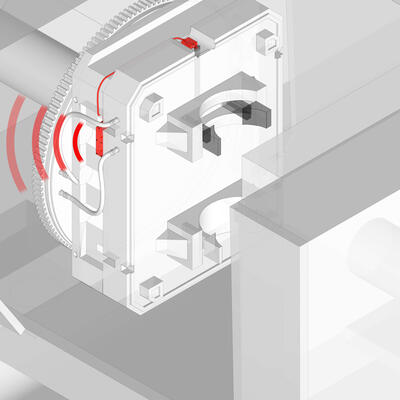

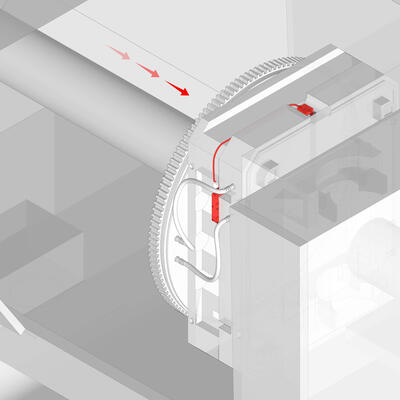

During the entire production process, a wireless transmitter communicates the slide position inside the injection moulding tool, and thus also correct closing. Both potential repair costs and the overall effort of production can be considerably reduced.

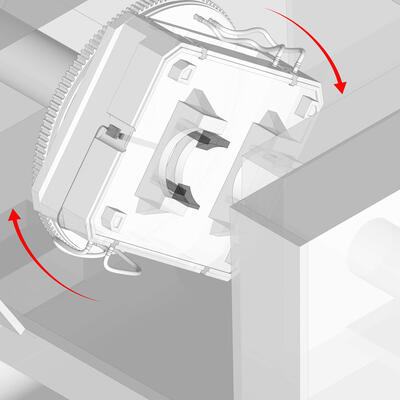

The challenge here: external cables are not an option because of the rotary plates.

This problem disappears when a steute wireless universal transmitter (e.g. RF 96 ST in combination with ES 13 W) is used. Rotation is no longer hindered, and the entire process can run smoothly.

This wireless solution is not restricted to a specific steute product. Depending on the individual application, it is also possible to use the RF I/O and RF 96 ST wireless universal transmitters in combination with wireless inductive sensors. Another option is to connect the RF 10 ST with an external switching contact (with gold contact elements).

Products for two-component injection moulding

Inductive sensors + universal transmitter

Position switch + universal transmitter