Particular challenges

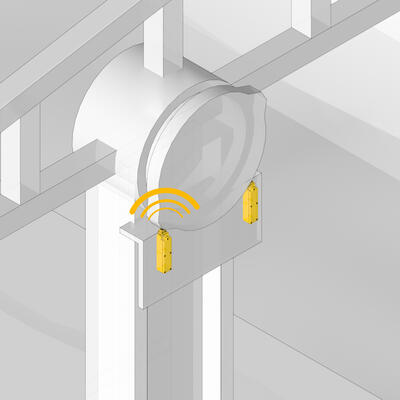

In extremely aggressive ambient conditions, such as storms, driving rain or tidal water, normal switches are soon out of their depth. Devices in nautical engine rooms additionally have to contend with extreme temperatures and strong vibrations.

Whether on drilling rigs, ship decks, LNG tankers or cranes in container ports: maritime applications demand from switches and sensors the highest quality and reliability at all times, for the sake of both personal and machine safety.

Our products

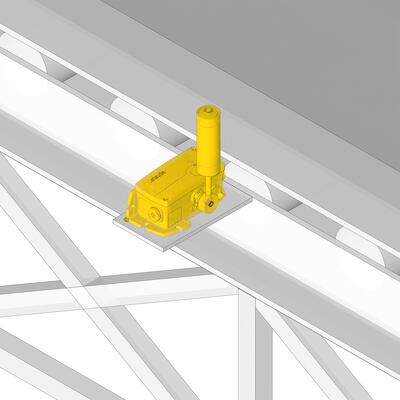

Highest product quality and top IP and corrosion protection combined with extremely robust enclosures make steute products the number one choice, both onshore and offshore.

Our switching devices are perfectly protected from different ambient conditions by especially developed enclosure variants. Our die-cast aluminium enclosure provides a very high level of corrosion protection thanks to its triple coating (passivation, priming, powder coating), while our shock-resistant thermoset enclosure is ideally suited to applications involving very aggressive media, such as fertilisers, iron ore or crude oil. This is the case during loading at ports or transportation at sea.

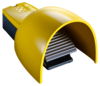

Our position switches, foot switches, belt alignment switches and emergency pull-wire switches are also available as explosion-proof variants. The reliability of our products is thoroughly tested, and this sometimes involves unusual field tests. Testing in real-life conditions facilitates an optimal orientation of our products to the special demands of this industry and guarantee extreme robustness and durability.

Product recommendations for maritime applications

In order to simplify the choice of a suitable device, our switches and sensors were assessed for two different types of maritime environment:

- Suitability for indoor areas (e.g. engine room)

- Suitability for outdoor areas (e.g. decks, cranes, ports)

Important assessment criteria included corrosion resistance, protection class and fouling resistance with regard to function.

We then translated the results of this assessment into four categories of suitability (highly recommended, recommended, suitable and conditionally suitable). These categories are further underlined in the product lists with easily recognisable quality seals.

Salt spray tests and IP protection classes

Various industrial standards exist for the testing and classification of corrosion resistance in metals with or without coatings. They begin with simple salt spray tests to DIN EN ISO 9227 and go all the way up to cyclic salt spray tests to IEC/EN 60068-2-52, which can run for several weeks. All of these standards define uniform laboratory conditions in order to guarantee reproducibility and thus results which are always comparable. Unfortunately, they seldom have a direct link to real-life practice. This is why some classification societies, such as the DNV-GL, are working on agreed internal standards for individual parts of the industry.

IP protection classes are defined, for example, in the IEC/EN 60529 standard. They refer to the protection of active elements, for example to prevent the touching of live parts or the penetration of water and/or dust. Protection classes for maritime applications start at IP65.

Field tests on the North Sea island of Helgoland

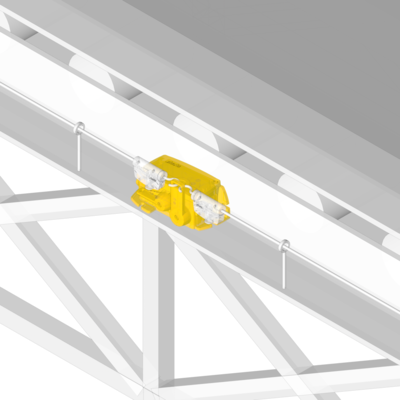

Results from salt spray tests are seldom adequate for a comparative assessment of the durability of different coating systems because the level of exposure to corrosion in laboratory tests is significantly different from that in real life. When protection classes are tested to the required standards, this always involves new devices. For this reason, steute complements its laboratory and other tests to the industrial standards with its own demanding, long-term tests in real-life conditions. The main evaluation criteria behind these tests are corrosion resistance, protection class and soiling sensitivity with regard to function.

In the first test phase, switches from our Extreme range were exposed to maritime outdoor conditions over a period of 12 months. In the test set-up, a representative selection of our devices was placed 1 metre above the surface of the water in the splash zone. After completion of the first test phase, the corrosion levels and functionality of the switches were evaluated, leading to a new practice-based benchmark to complement the laboratory tests: a benchmark which represents the typical climatic conditions over an entire year on site in Helgoland in the middle of the North Sea.

Application examples